Did you ever wonder on the exact way machines are formed? It's pretty fascinating! CNC machining is a key component of this process. CNC (Computer Numerical Control) These are machines that small,highly accurate parts for precision engineering. They are key components that find applications in a wide range from airplanes, hospitals and car factories. Manufacturing these parts without the use of CNC machining would be far more difficult and labour intensive.

There are machines all over the place on factories! They do everything from manufacture the products used every day in our daily lives. These machines are continuously improved to work more quickly and efficiently. This process requires the help of CNC machining parts and these are used in majority of such machines. Such elements are nuts and mounting screws or more complex parts, e.g. gears & motors Most importantly, this is what makes CNC machining so efficient in the industrial world where both simple and complex parts are required.

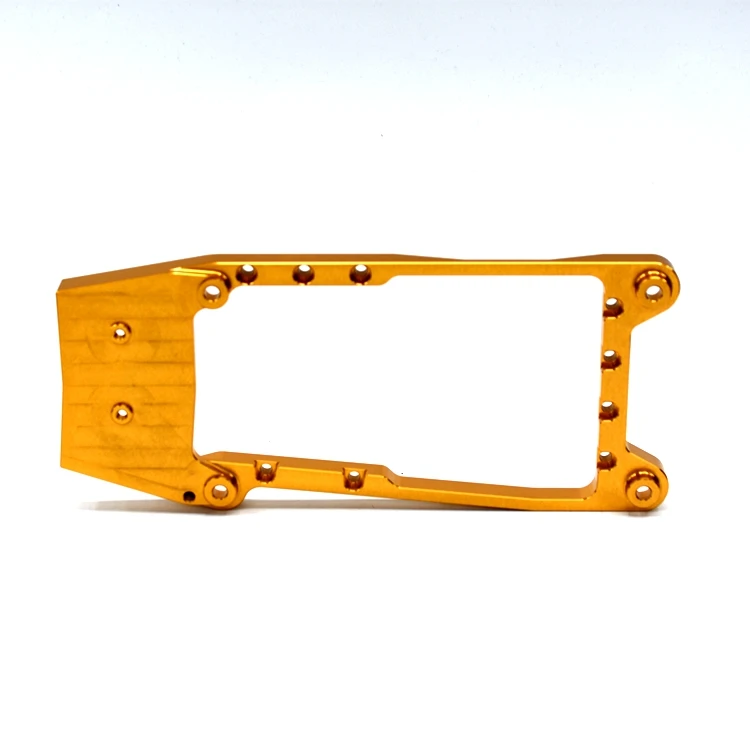

Proposition: Therefore, here is how these parts are made Keep it going… CNC machining involves a raw material piece, such as metal or plastic. After the material is selected a computer program tells the machines how to cut and shape that stuff into just what they needed for their part. This is a very precise process that can make complex designs this way, and it does quickly. These parts are produced to exact specifications as directed by the computer, so they rarely fail.

Quality materials - using Good Materials for High-Quality CNC Parts This material type is dependent on the final application end use of that part being made. As an example, we can point to certain types of material that have properties enabling them to withstand being in a hot environment without disintegrating into nothing. For lightweight parts that still have to be strong, the sections might be manufactured from a unique type of heavy-duty plastic or another composite material. Selecting the correct materials is critical so that parts function correctly and have a long lifetime.

CNC machining offers the advantage to making parts tailored specifically for your use case. So you can design special one for different use which is help in many industry. For example, medical equipment needs components that are clean and sterile or lightweight. Consequently, CNC machining proves to be the ideal procedure for producing these types of components. This individuality makes possible the creation of new designs that are required to be safe and effective.

our range of products includes an array of high-precision parts for medical equipment as well as aerospace which includes parts used in heart stents we also offer durable and reliable parts for cnc complex machining parts we're committed to meeting these industries' needs in terms of material performance precision and innovation while ensuring that every item is manufactured to the most rigorous standards we fulfill the needs of our clients with top quality and cutting-edge technology

Yuyao Phelp Electric Appliance Co., Ltd which is one of the top three exporters of the citrus juicer in China is always leading in the market with its cnc complex machining parts and top-quality service. We are always striving to improve our blender and juicer products by constantly analyzing and developing more novel designs, and more durable products that satisfy the needs of our customers.

Our supply chain integrates everything from simple materials acquisition to advanced processes like electroplating alloy processing oxidation and treatment of surfaces The thorough cnc complex machining parts and stringent quality control make sure that every stage is up to high quality standards This results in effective consistent and high-quality products and services that increase the customer's satisfaction

In terms of the quality of our products we've set up an efficient management system approved by ISO 9001 cnc complex machining parts ISO 14001 AS9100D and IATF 16949 and equipped with the latest inspection equipment and a professional quality inspection team From the inspection of raw materials to the final delivery Our quality control procedure assures that each product meets or surpasses the international standards We continuously improve production processes and train our employees regularly in quality management to enhance the quality standards we set for ourselves

Copyright © Huizhou Jiyan Hardware Co.,Ltd All Rights Reserved | Privacy Policy