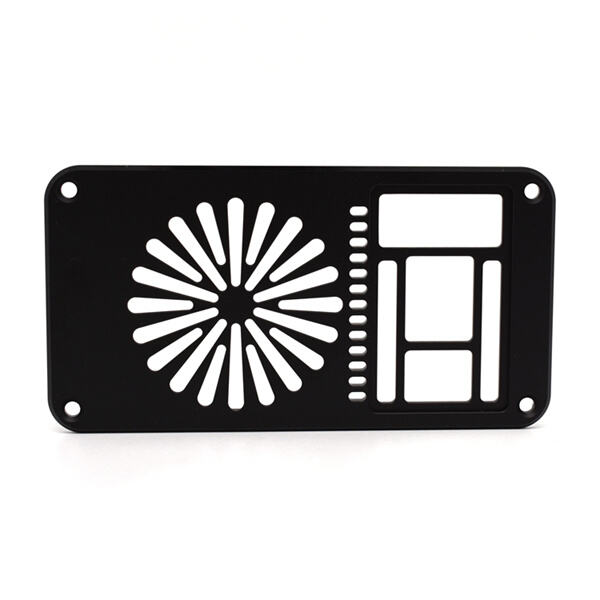

Observe, the high-end and sturdy CNC machining milling is a unique strategy to build things by turning into order& that have constrained processing massesongs. These are the computers which instruct machines to cut materials like metal or plastic. The machines let the parts know that, by following their instructions they can be just as intact and comfortable lift capable with exactly the right shape and size to fit one another. This method is fancy because it permits very accurate cuts therein everything is factory-made properly.

There are so many reasons why CNC machining milling is one of the most valuable things that you can do. First and foremost, it delivers repeatable reality-oriended parts. Consider you need a toy or machine with many parts; every part will look and function exactly as the others using CNC machining. This is very efficient especially for big factories needing to work in bulk orders. The time saved means that them workers are freed up to work on more important tasks and less mistakes will be made by the machines doing all of the dirty work.

It might sound complicated to get a CNC machine up and running but it is just some steps that you will need to follow correctly. To begin with, choose the category of the machine you need to make parts according to size and type. Similarly, different machines do best for certain tasks and it better to chose the perfect machinerente grinder.

Once your frame is built, you can load the material on to a CNC machine and hold it in place. You want to be certain that the material does not move while being cut by any of this equipment. Once your material is in place and everything is secured, you can start the machine up and watch it as cuts out exactly what you designed.

While using the CNC machines forms a perfect way of making parts there can be instances when things go haywire. A lot of times people using incorrect settings/tolerances. If those settings are wrong, then our part will be dimensionally incorrect and the galley print we make to send out with your finished parts at every order may cause issues.

Imprecise and improperly securing the material is another mistake. If the material is not properly secured during cutting, this can lead to the wrong position of parts and subsequent errors in their production. So how can you avoid making these same mistakes, this is why it's super important to verify your settings and that everything is safe before turning the machine on.

There are a lot of extremely important things to consider when designing parts for CNC machining. Resolve: Think about which material you want to use, how big the part is going to be and everything that needs precision with this conception. Ensure you are modeling everything like the holes, curves or cutouts that will be required in the final piece.

Copyright © Huizhou Jiyan Hardware Co.,Ltd All Rights Reserved | Privacy Policy