We have a myriad of machines to assist in our creative production are creating things. One crucial machine is the CNC turning milling machine. A special machine that helps to create parts in metals, plastics or wood. These parts need to be made reliably because without them they may not function properly. In this article, we will dig deeper into the CNC turning milling parts to know why they are highly demanded for different products.

Since we live in the future, CNC turning milling machines are quite impressive as well because they move based on how a computer tells them to. In other words, they are perfectly precise since they stick to the program just as it is written in the computer. So that high precision is what allows them to make matching parts for specific things. Moreover, these machines are also extremely quick. They are also able to manufacture the parts in a faster way, which is very important as time means money. Well, faster parts manufacturing equals the ability to produce more of an item for less cost in labor or materials.

Items get developed with much more customization which include their suitable meeting when they may be designed through a CNC turning milling machine. It was very useful when we deploy them into a more common machine or product. The better the parts fit, the better they work together and produce an overall better quality product. Higher-end parts even fit better and cause the product to retain their adherence due to less abrupt/rough shifts out-of-the-box. The better constructed parts means the replacement part is more likely to last for a longer period of time when in use, which everyone prefers.

CNC turning milling parts are in many of the products and machines we see around us each day. They are even used in cars, airplanes, computers and toys to name a few. These components are designed as service-specific(they can be placed into various types of products). This is quite useful as it means the same parts can be used across many different pieces, making manufacture significantly simpler and more efficient. Manufacturers can build a broad range of diverse products with such parts, saving them the need to design new ones from scratch for each.

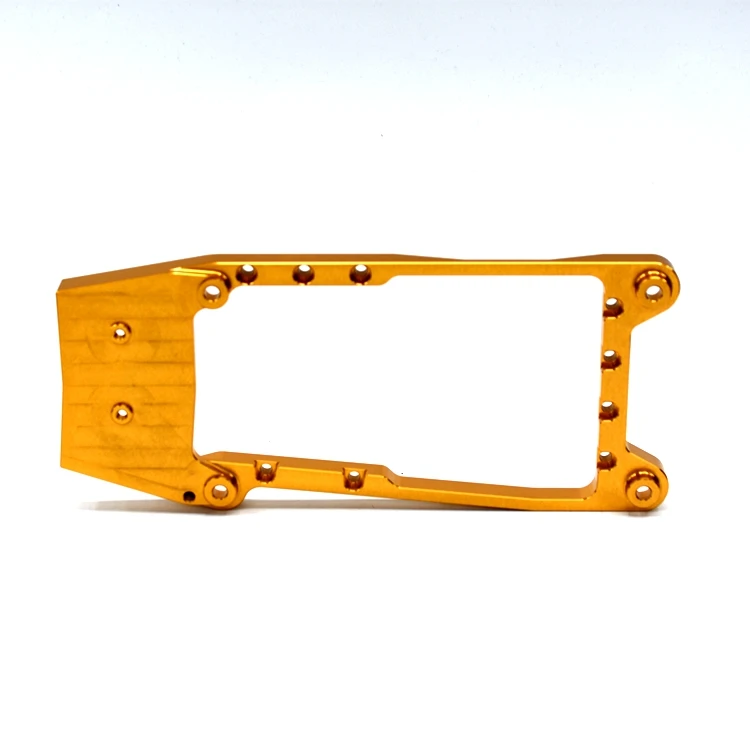

One of those types or styles is the CNC turning milling parts, known to produce quality products. These parts are machined from high-precision machines and made according to the specified drawing. This equates to good inter-opt: they work well together and are less likely to break easily. The use of high-quality parts is vital as it results in a longer life and more reliability from any product for which they are applied. Consumers want to pay for great products and why consumers trust the facturing of betteryes(workshopclub) a way, and having high-quality parts can help ensure that happens.

It is also cost effective - using the CNC turning milling parts can save you a lot of money in the long term When the parts are manufactured quickly and with high efficiency it results in low cost of production. Moreover, due to the great quality material used are new parts will be durable. Save money down the line as any product requiring these parts (which is pretty much every single modern product) will need less repairs or replacements of them. Lower production costs and maintenance are always beneficial - it means that companies can pass those savings onto customers, which everyone enjoys.

our product range includes a wide array of precision parts for the automotive industry aerospace industry medical equipment including the highest-quality components for heart stents and also durable and reliable components for industrial machinery our aim is to meet the requirements of these industries in terms of material performance precision and innovation we make sure that all products comply with the most cnc turning milling parts we fulfill the needs of our customers with superior quality and cutting-edge technology

Our supply chain that is integrated cnc turning milling parts everything from basic material procurement through to complex processes such as electroplating treatment of surfaces and titanium alloy reduction The thorough approach and stringent quality control ensure that each stage is up to high quality standards The result is effective quality consistent and reliable products and services that improve customer satisfaction

We have a complete quality control system that's accredited with ISO 9001 ISO 13485 ISO 14001 cnc turning milling parts and IATF 16949 It also comes with advanced tools for inspection as well as a team of professional quality inspectors Our quality assurance process encompasses every stage from the initial inspection of raw materials to final product delivery ensuring that every product is in line with or surpasses international standards and customers' expectations We continuously improve production processes and regularly train our employees in quality management to improve our quality management practices

Yuyao Phelp Electric Appliance Co., Ltd., one of China's cnc turning milling parts citrus juicer exporters is leading the industry with its design innovations and quality of service. We continue to enhance our blender and juicer products, continually researching and creating new designs and better quality to satisfy the needs of our customers.

Copyright © Huizhou Jiyan Hardware Co.,Ltd All Rights Reserved | Privacy Policy